自动点焊机大家都耳熟能详,现在工厂应用的很广泛但是它的前世今生你们知道吗?请看下面的文章!

自动点焊机(spotweldingrobot)用以焊接全自动工作的工业机器人。全世界第一台螺母点焊机于1965年刚开始应用,是英国Unimation企业发布的Unimate自动点焊机,我国在1987年自主研发成第一台焊接自动点焊机──华宇-Ⅰ型焊接自动点焊机。

中文名字焊接自动点焊机英语名(spotweldingrobot)用以焊接全自动工作的工业机器人构成自动点焊机本身、电子计算机自动控制系统功效焊接

(4)产品升级工业机器人与自动化技术成套设备武器装备具有细致生产制造、细致生产加工及其

自动点焊机介绍英文版

Everyone knows the automatic spot welding machine. Now the factory is widely used, but do you know its past and present life? Please see the following article!

Spotweldingrobot is used for welding fully automatic industrial robots. The world's first nut spot welder just started application in 1965. It is a Unimate automatic spot welder released by the British company Unimation. In 1987, China independently

developed the first automatic weld spot welder—Huayu-Ⅰ welding. Automatic spot welding machine.

Chinese name Welding automatic spot welding machine English name (spotweldingrobot) Used to weld fully automatic industrial robots to constitute the automatic spot welding machine itself, electronic computer automatic control system effect

welding

The automatic welding spot welding machine is composed of the automatic spot welding machine itself, the electronic computer automatic control system, the teaching box, and the welding welding welding system software, because in order

to integrate the working standard of the convenient posture, the general welding robot uses the basis of the bone joint industrial robot The design concept generally has six playability: waist rotation, hind arm rotation, arm rotation, wrist rotation,

wrist swing and wrist twist. There are two types of drive methods: hydraulic drive and electrical equipment drive. Among them, the electrical equipment driver has the advantages of simple maintenance, low power consumption, high speed, high accuracy,

and good safety factor, so it is widely used. Welding automatic spot welder carries out welding work in accordance with the posture, sequence and main parameters required by the gait analysis program flow. The entire process is completely automated

and equipped with a socket for communication with peripheral equipment, which can accept the upper level according to this socket Main control chip and management method The operation instructions of the electronic computer are underway.

Application

Writing

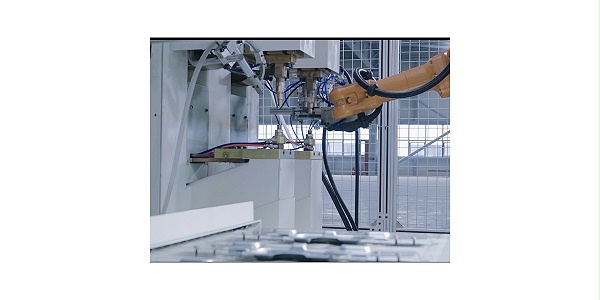

The industry with the largest number of welding automatic spot welders is supposed to be a fully automatic production workshop for car bodies. (See below)

Welding automatic spot welder production and processing car body

shell (color gallery: KUKA)

Welding automatic spot welder production and processing car body shell (color gallery: KUKA)

Technical characteristics writing

(1) Technical comprehensive strong industrial robots and automation technology

complete sets of equipment are technical, centralized and combined with a variety of courses, involving a variety of technical fields, including industrial robot control systems, automatic spot welding machine dynamic models and simulation, automatic

The spot welding machine builds finite element analysis, laser cutting processing technology, modular design and programming design, intelligent precision measurement, model production and processing integration, factory automation and detailed freight

logistics, and other intelligent manufacturing technologies.

(2) Main uses Universal industrial robots and automation technology complete sets of equipment Weapons and equipment are the main equipment in the processing process and can be used

in the manufacturing stages of manufacturing, installation, inspection, freight logistics, etc., and are widely used in trolleys, entire vehicles and auto parts, Construction machinery and equipment, urban rail, low-voltage electrical, power engineering,

IC weapons and equipment, military, cigarettes, financial industry, pharmaceutical industry, metallurgical industry, packaging, printing, publishing and other manufacturing industries, the main uses are very common.

(3) Outstanding technical

industrial robots integrate intelligent manufacturing technologies such as precision, flexible production, intelligent systems, and application software development and design. Based on the inspection, manipulation, promotion, production scheduling,

management methods and management decisions of the entire process, maintenance is maintained. Increasing production volume, ensuring quality, controlling costs, reducing resource consumption and air pollution are the biggest reflections of industrial

control automation standards.

(4) Product upgrades Industrial robots and automation technology Complete equipment Weapons and equipment have meticulous manufacturing, meticulous production and processing, and