点焊机器人(点焊机器人)一种对于自动点焊操作的工业机器人。世界上第一台点焊机始于1965年。它是Unimation在美国推出的Unimate机器人。 1987年,中国研发了第一台点焊机器人华宇I型点焊机器人。

中文名

点焊机器人

外文名称

(点焊机器人)

对于

自动焊接工业机器人

组成

机器人主体,计算机控制系统

的角色

点焊

目录

1个优点

2用途

3技术特点

4相关信息

5发展趋势

优点

编辑

点焊机器人由机器人主体,计算机控制系统,示教盒和点焊焊接系统组成。为了适应灵活运动的要求,焊接机器人通常使用铰接式工业机器人的基本设计,该机器人通常具有六个自由度:腰部旋转,手臂旋转,手臂旋转,腕部旋转,腕部摆动和腕部扭转。驱动方式有两种:液压驱动和电动驱动。其中,电驱动器具有易于维护,能耗低,速度快,精度高,安全性好等优点,因此得到了广泛的应用。点焊机器人根据教学过程中指定的动作,顺序和参数执行点焊操作。该过程是完全自动化的,并且具有与外部设备进行通信的界面。该接口可用于接受上级主控制和管理计算机。控制命令起作用。

应用

编辑

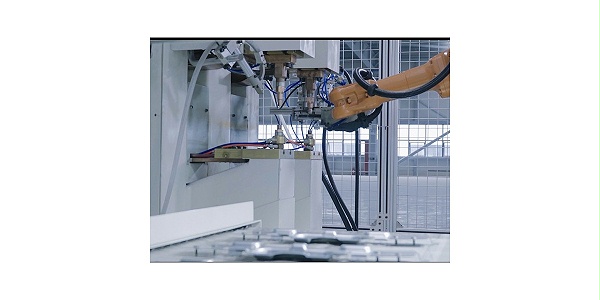

点焊机器人使用最广泛的领域应该属于车身装配车间。 (见右图)

点焊机器人加工车身外壳(来源:KUKA)

技术特征

编辑

(1)技术综合能力强。工业机器人和自动化技术集成和集成了多个学科,涉及多个技术领域,包括工业机器人控制技术,机器人动力学和仿真,机器人结构有限元分析,激光加工技术模块化编程,智能测量,建模和先进制造技术,例如加工集成,工厂自动化和精细物流在技术上非常全面。

(2)广泛的应用领域工业机器人和自动化设备是生产过程中的关键设备,可对于制造,安装,测试,物流等生产环节,并广泛应对于整车,汽车零部件,工程机械等。 ,轨道交通低压电器,电力,集成电路设备,军工,烟草,金融,医药,冶金,印刷出版等许多行业都有广泛的应用。

(3)先进技术机器人集成了先进的制造技术,例如精度,灵活性,智能性和软件应用程序开发。通过对过程的检测,控制,优化,调度,管理和决策,增加产量,提高质量并降低成本。成本,减少资源消耗和环境污染是工业自动化的最高体现。

(4)技术升级工业机器人和自动化设备具备精加工,精加工和灵活生产等技术特征。它们是新一代的生产工具,可扩展动力机器和计算机之后人们的身体和智力。数字化,自动化,联网和智能化的重要手段。 [1]

相关信息

编辑

点焊机器人的操作步骤

1.确保水和电完好无损,并释放安全门和光栅的警报。

2.当机器人处于手动状态时,将机器人光标移至警报栏,然后按All确认已启用焊接功能(示教盒屏幕左下角的蓝色按钮不在十字形内)。州)。

3.在机器人示教盒上选择输入/输出接口,检查是否重置了机器人的工作信号和工作完成信号,如果没有重置,请进行重置;然后将机器人示教盒上的状态选择开关转到自动位置。示教器上的程序指针将指向CELL主程序。 (如果示教盒上的程序指针未指向CELL主程序,则需要将机器人示教盒上的状态选择开关转到手动文件,然后在R1文件夹Cell程序中将其选中(按Enter选择)),然后将机器人示教盒上的状态选择开关切换到自动档},机器人将切换到自动操作状态。

4.按下主控制台上的警报重置按钮,然后将手动/维护/自动选择开关设置为自动位置。

5.确认示教盒上的程序指针是否指向CELL主程序。

6.开启伺服电源:同时按下操作箱上的伺服电源按钮,开启定位器的伺服电源,相应的绿色伺服电源灯亮,并确保报警器红灯亮重置并关闭。如果没有,请按几次此重置按钮。然后按下启动按钮(2s),同时相应的指示灯亮起,工作站将进入自动运行状态。

简单的问题处理

1.如果机器人由于任何原因停止,请同时手动按下机器人和操作框,然后按一次或两次按操作框上的警报复位,然后将机器人光标移至报警栏,然后按全部确认重置警报,然后自动单击示教器,然后重复上述步骤6。

2.如果电极头掉落,则在其他机器人完成工作后,将示教盒和手术台切换为手动T1模式。如果安装方便,请按按钮并重新启动机器人。重置警报,将机器人光标移至警报栏,然后按全部进行确认,重置警报,然后将示教盒设置为自动,然后重复上述步骤6);如果安装不方便,则需要将机器人移动到“位置”(不要撞到任何东西),更换后,将机器人移动到“停止”位置之前的位置(将机器人移动到靠近该位置的位置),然后选择该点到该点,并按住进行检查,直到机器人自动停止并确保在此过程中不会碰撞为止,只需重新启动即可。

发展趋势

编辑

点焊机器人的首次大规模使用将出现在发达地区。随着产业转移的进行,发达地区的制造业需要升级。基于增加工人成本的现实,点焊机器人的应用已成为最佳选择。未来,中国点焊机器人的大规模应用将集中在广东,江苏,上海,北京等地,其点焊机器人将占全国的一半以上。点焊机器人市场的增长及其巨大的市场潜力吸引了世界著名机器人制造商的关注。目前,从中国进口的点焊机器人主要来自日本,但是随着诸如“机器人”之类具有自有知识产权的公司的不断涌现,中国将越来越多地生产点焊机器人。

英文版:

Spot welding robot

Spot welding robot (spot welding robot) is an industrial robot for automatic spot welding operations. The world's first spot welding machine started in 1965. It is a Unimate robot launched by Unimation in the United States.

In 1987, China developed the first spot welding robot Huayu I spot welding robot.

Chinese name

Spot welding robot

Foreign name

(Spot welding robot)

for

Automatic welding industrial robot

composition

Robot main body, computer control system

character of

spot welding

Spot welding robot

table of Contents

1 advantage

2 uses

3 Technical characteristics

4 related information

5 Development Trend

advantage

edit

The spot welding robot is composed of a robot body, a computer control system, a teaching box and a spot welding welding system. In order to adapt to the requirements of flexible movement, welding robots usually use the basic design of

articulated industrial robots, which usually have six degrees of freedom: waist rotation, arm rotation, arm rotation, wrist rotation, wrist swing and wrist twist. There are two drive modes: hydraulic drive and electric drive. Among them, the electric

drive has the advantages of easy maintenance, low energy consumption, fast speed, high precision, good safety and so on, so it has been widely used. The spot welding robot performs the spot welding operation according to the actions, sequences

and parameters specified in the teaching process. The process is fully automated and has an interface to communicate with external devices. This interface can be used to accept superior master control and management computers. Control commands

work.

application

edit

The most widely used field of spot welding robots should belong to the body assembly workshop. (See picture on the right)

Spot welding robot processing body shell (Source: KUKA)

Technical characteristics

edit

(1) Strong technical comprehensive ability. Industrial robots and automation technology integrate and integrate multiple disciplines and involve multiple technical fields, including industrial robot control technology, robot dynamics and

simulation, finite element analysis of robot structure, laser processing technology modular programming, intelligent measurement, modeling and Advanced manufacturing technologies, such as processing integration, factory automation and fine logistics

are very comprehensive in technology.

(2) Wide application fields Industrial robots and automation equipment are the key equipment in the production process, which can be used for manufacturing, installation, testing, logistics and other production links, and should be widely

used for vehicles, auto parts, and construction machinery. , Rail transit low-voltage electrical appliances, electricity, integrated circuit equipment, military industry, tobacco, finance, medicine, metallurgy, printing and publishing and many

other industries have a wide range of applications.

(3) Advanced technology robot integrates advanced manufacturing technology, such as precision, flexibility, intelligence and software application development. Through the detection, control, optimization, scheduling, management and decision-making

of the process, increase production, improve quality and reduce costs. Cost, reducing resource consumption and environmental pollution are the highest manifestations of industrial automation.

(4) Technical upgrade Industrial robots and automation equipment possess technical characteristics such as finishing, finishing and flexible production. They are a new generation of production tools that can expand people's bodies and intelligence

behind power machines and computers. An important means of digitization, automation, networking and intelligence. [1]

Related Information

edit

Operation steps of spot welding robot

1. Make sure the water and electricity are intact and release the alarms of the safety gate and light grid.

2. When the robot is in the manual state, move the robot cursor to the alarm bar, and then press All to confirm that the welding function is enabled (the blue button in the lower left corner of the teaching box screen is not inside the

cross). State).

3. Select the input / output interface on the robot teaching box, check whether the working signal and work completion signal of the robot are reset, if not reset, please reset; then turn the state selection switch on the robot teaching

box To the automatic position. The program pointer on the teach pendant will point to the CELL main program. (If the program pointer on the teaching box does not point to the CELL main program, you need to turn the status selection switch on the

robot teaching box to the manual file, and then select it in the Cell program in the R1 folder (press Enter to select)), Then switch the state selection switch on the robot teaching box to automatic mode}, and the robot will switch to the automatic

operation state.

4. Press the alarm reset button on the main console, and then set the manual / maintenance / automatic selection switch to the automatic position.

5. Confirm whether the program pointer on the teaching box points to the CELL main program.

6. Turn on the servo power: simultaneously press the servo power button on the operation box to turn on the servo power of the positioner, the corresponding green servo power light is on, and make sure that the red light of the alarm is

reset and turned off. If not, please press this reset button several times. Then press the start button (2s) and the corresponding indicator lights up, the workstation will enter the automatic operation state.

Simple problem handling

1. If the robot stops for any reason, please manually press the robot and the operation frame at the same time, then press the alarm reset on the operation frame once or twice, then move the robot cursor to the alarm bar, and then press

all to confirm the reset alarm, Then click the Teach Pendant automatically and repeat step 6 above.

2. If the electrode head is dropped, after other robots complete the work, switch the teaching box and operating table to manual T1 mode. If the installation is convenient, press the button and restart the robot. Reset the alarm, move the

robot cursor to the alarm bar, then press all to confirm, reset the alarm, then set the teaching box to automatic, and then repeat the above step 6); if the installation is not convenient, you need to move the robot to " "Position" (do not hit

anything), after replacement, move the robot to the position before the "stop" position (move the robot to a position close to the position), then select the point to the point, and press and hold to check, Until the robot automatically stops

and ensures that it will not collide during this process, just restart it.

development trend

edit

The first large-scale use of spot welding robots will appear in developed regions. As the industrial transfer proceeds, the manufacturing industry in developed regions needs to be upgraded. Based on the reality of increasing worker costs,

the application of spot welding robots has become the best choice. In the future, large-scale application of spot welding robots in China will be concentrated in Guangdong, Jiangsu, Shanghai, Beijing and other places, and its spot welding robots

will account for more than half of the country. The growth of the spot welding robot market and its huge market potential have attracted the attention of world-renowned robot manufacturers. At present, spot welding robots imported from China are

mainly from Japan, but as companies such as "robots" with their own intellectual property continue to emerge, China will increasingly produce spot welding robots. [2]